The Magic Behind 3D Printing: What Stuff Makes Those Cool Objects?

(What Is The Material Used In A 3d Printer To Print Called)

You’ve seen 3D printers create toys, tools, even parts for rockets. But what’s the secret ingredient that turns digital designs into real things? Let’s talk about the star of the show: the material that makes 3D printing possible.

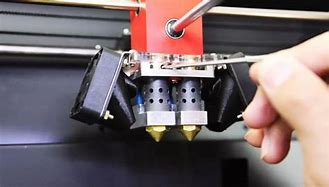

First off, the stuff used in 3D printing has a simple name—filament. Think of it like high-tech glue sticks. Most home printers use this. Filament comes in spools, like thread for a sewing machine. You feed it into the printer, it gets melted, and the machine layers it to build your object. Simple idea, but the materials themselves are anything but ordinary.

The most common type is PLA. PLA stands for polylactic acid. Don’t let the fancy name scare you. It’s made from cornstarch or sugarcane. Yes, your 3D-printed dinosaur might literally come from plants. PLA is popular because it’s easy to use, smells like candy when heated, and works for things like phone cases or decorative pieces. It’s not great for high heat, though. Leave a PLA cup in a hot car, and it’ll warp faster than ice cream in the sun.

Next up is ABS. This is the tough guy of filaments. ABS is the same plastic used in LEGO bricks. It’s stronger than PLA and handles heat better. Print a car part or a tool handle with ABS, and it’ll last. But there’s a catch. ABS needs a printer with a heated bed. Without it, the plastic might curl up like bacon in a pan. It also smells like burnt plastic when printing—not exactly a fresh-baked cookies vibe.

Then there’s PETG. This stuff is like the middle child between PLA and ABS. It’s strong, flexible, and water-resistant. People use it for outdoor items or things that need to bend a little, like snap-on lids. PETG doesn’t mind heat, either. Just don’t try to print it too fast. It’s picky about speed and might blob if rushed.

But wait—there’s more. Some printers use resin instead of filament. Resin looks like sticky syrup and comes in bottles. It’s for printers that use UV light to harden the material layer by layer. Resin prints are super detailed. Think tiny jewelry or dental molds. The downside? Resin is messy. You need gloves, alcohol for cleaning, and patience. Plus, uncured resin is toxic. This isn’t a “spill it on the couch” kind of material.

Ever heard of flexible filament? This stuff is like rubber. Print a squishy phone case or bendy robot parts. It’s fun but tricky. The filament stretches, so the printer has to push it slowly. Too fast, and the material might jam. It’s like trying to squeeze toothpaste out evenly—it takes practice.

What about metal or wood? Yep, those exist too. Some filaments mix PLA with wood fibers or metal dust. Print a vase that looks like birchwood or a ring with a metallic shine. These materials feel real but need special nozzles. Wood filament can clog a printer if it’s not set up right. Metal-filled filament can sand and polish like actual metal. Just don’t expect it to survive a trip through a volcano.

Then there’s the weird stuff. Conductive filament for circuit parts, glow-in-the-dark plastic for Halloween props, even dissolvable material for temporary supports. The options keep growing.

So why does the material matter? Picking the right one decides if your print works or fails. Need something food-safe? Check if the filament is certified. Building a part for a drone? Go for strength and heat resistance. Making a cosplay prop? Maybe go lightweight and colorful.

(What Is The Material Used In A 3d Printer To Print Called)

Filament isn’t just plastic—it’s the lifeblood of 3D printing. Without it, printers are just fancy boxes. With it, they can build almost anything. Next time you see a 3D-printed object, remember: the magic isn’t just in the machine. It’s in the material that makes imagination real.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)