Approach 1: Improve technical degree, support item high quality, and reinforce technical gets:

According to the study, just a couple of manufacturers of polycarboxylic acid water reducer products in my nation are separately developed, and many other suppliers present modern technology from university research institutions or study institutes or directly introduce modern technology from various other business to begin production. As a result of the restricted technological strength of the manufacturers themselves, they do not have a deep understanding of the polycarboxylic acid water reducer innovation they generate, and it is tough to adjust to different modifications in basic materials and processes, and there is no other way to discuss the stability of product top quality. For that reason, it is suggested that polycarboxylic acid water-reducing representative producers actively accept universities and research institutes to fully understand the numerous aspects impacting the efficiency of polycarboxylic acid water-reducing agent products, readjust the synthesis process parameters in a timely fashion to support item high quality, and enhance technological reserves via joint or independent r & d to adjust to market demand. On top of that, the early release of polycarboxylic acid water-reducing agent resources requirements and the stability of polycarboxylic acid water-reducing representative basic material rates are also extremely essential to make certain the stability of polycarboxylic acid water-reducing agent product efficiency.

Approach 2: Idea in examination results rather than product specs

Some items that are fantastic in the water-reducing agent requirements, or perhaps products with superb test outcomes, may not appropriate for a specific job. As a matter of fact, some products may satisfy the demands of concrete product preparation for a particular project although the test results are not extremely outstanding. Additionally, because of changes in basic materials, the examination results throughout job bidding can not stand for the real application of the job. GB50119-2003 “Technical Specifications for Application of Concrete Admixtures” “2.1.4” clearly stipulates: The raw materials used in concrete with admixtures, such as concrete, sand, stone, admixtures, and admixtures, shall abide by the provisions of the pertinent national criteria in force; when trial-mixing concrete with admixtures, the raw materials used in the project shall be utilized, and the test things shall be established according to the style and building and construction requirements. The test problems will coincide as the building conditions. When the raw materials used in the job or the concrete performance requirements alter, the trial-mixing examination shall be conducted again.

(Cabr superliasticizer)

Method 3: Prevent get in touch with in between polycarboxylic acid water reducers and iron materials

For polycarboxylic acid water reducer manufacturers and vendors, special manufacturing tools and assembly line shall be used to synthesize and compound polycarboxylic acid water reducers, and polycarboxylic acid water reducers will not be synthesized or intensified utilizing the exact same assembly line as other water reducers. In addition, the transportation and storage of polycarboxylic acid water reducers will not utilize iron products (other than stainless steel) yet plastic, glass and other products. Call with iron occasionally triggers modifications in the efficiency of polycarboxylic acid water reducers.

Approach 4: Resolutely avoid blending other types of admixtures

It is strictly forbidden to blend various other water reducers or various other kinds of admixtures. There are 2 meanings. Initially, the compounding of polycarboxylic acid water reducers (such as with lignin sulfonate, air entrainment, defoaming, retarding and other parts) can only be carried out by admixture suppliers or providers. The user of the water reducer, that is, the concrete preparer, just needs to examine and store its appropriate efficiency. Nothing else components might be compounded in it, nor might other components be mixed in it because of oversight. It is definitely prohibited to use pumps and metering devices for pumping and metering other admixtures without cleaning. One more significance is that concrete mixing devices, transportation automobiles, and pumping equipment are best made use of for concrete mixed with polycarboxylic acid water reducers. When sharing blending equipment, transportation cars and pumping tools, these devices must be completely cleaned up before they can be made use of for concrete combined with various other sorts of admixtures, and the other way around.

Technique 5: Strictly measure the water reducer and mix water

When preparing concrete mixes with polycarboxylic acid water reducers, the ideal water reducer dose and water intake established by the laboratory should be purely measured. Do not enhance the water reducer dose or water usage at will to stay clear of negative phenomena such as segregation, blood loss, solidifying, and boosted air web content in the blended concrete, which will impact the typical pumping building and construction and pouring high quality of the concrete.

The moisture had in the raw products sand and rock accumulations need to be precisely determined and deducted from the complete water usage to prevent unfavorable consequences triggered by unreliable detection of the wetness contained in the sand and rock accumulations.

( concrete addtives)

Technique 6: Appropriately encounter the compatibility issue of polycarboxylic acid water reducers and cement/admixtures

The compatibility problem of admixtures and cement/admixtures has a long history. Throughout the years, the adaptability research study work on naphthalene-based high-efficiency water-reducing agents and their compound items has achieved great results:

With the effort of researchers, concrete preparers, admixture suppliers, cement and admixture manufacturers, concrete fitters and supervisors have collectively identified this trouble, changing the scenario in which admixture manufacturers and distributors have actually constantly presumed all responsibilities.The incompatibility of admixtures and cement/admixtures is attributed to several influencing variables, and extensive study has actually been executed on their affecting legislations. A series of effective options have been explored for the details conflict between admixtures and cement/admixtures.

Approach 7: Purely manage the resonance span and vibration time

Since the slump of concrete prepared with polycarboxylic acid-based water-reducing agents is usually huge and the thickness of the combination is reduced, the resonance radius and vibration time after the concrete mixture is poured need to be figured out with experiments or must be directed by experts. Mean the resonance span is as well tiny or the resonance time is too long. In that situation, it is very easy to cause structural flaws such as a significant decline in concrete air material and severe stratification of the accumulated phase and paste stage.

Technique 8: Enhance first upkeep and prevent splitting.

On any type of occasion, for any concrete mix, first and later maintenance after putting is very essential.

Polycarboxylic acid water reducer has little result on the contraction efficiency of concrete; in other words, the addition of polycarboxylic acid water reducer does not excessively enhance the shrinkage of concrete, which does not indicate that the concrete with polycarboxylic acid water reducer can relax or perhaps terminate the maintenance.

Like concrete with other admixtures, the second surface area smearing, movie covering or splashing of concrete with polycarboxylic acid water reducer after putting and vibration is really reliable in avoiding its plastic contraction fractures. Constant 7d or 14d moisturizing upkeep is not just essential for the normal growth of concrete stamina but additionally an assurance to stop its drying out contraction splits.

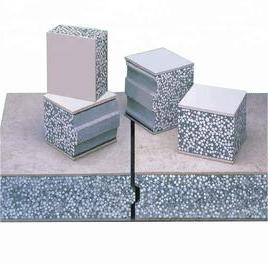

( foamed concrete)

In order to boost the crack resistance of concrete with polycarboxylic acid, it is additionally essential to include a certain quantity of fiber, and this kind of concrete still requires good wet curing to make certain that the framework does not split.

Approach 9: Construction and monitoring units ought to function closely with concrete prep work and admixture distributors

In the task, it is unpreventable to run into numerous technological problems, technological conflicts and even problems and disputes triggered by engineering accidents. The best goal of all parties associated with the job is to ensure the smooth development of the project and the quality of the project. The history of polycarboxylic acid water reducers in production and application in actual projects is very brief, and the gathered engineering experience can be much better. It is very easy to experience application problems and also result in design accidents at this time, the building unit or monitoring device requires to function closely with the concrete preparation, polycarboxylic acid water reducer production and supply, and cement/admixture production and supply from a technical perspective and perform thorough analysis to recommend effective remedies.

Distributor

Cabr-Concrete is a supplier of Concrete Admixture with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high quality Concrete Admixture, please feel free to contact us and send an inquiry.

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us