Scientists at Stanford College in the United States have created a brand-new high-speed micro-scale 3D printing innovation – roll-to-roll constant fluid user interface manufacturing (r2rCLIP), which can print 1 million incredibly great and adjustable micro-particles each day. This achievement is anticipated to advertise the growth of biomedicine and other areas. The pertinent paper was published in the most recent problem of “Nature” on the 13th.

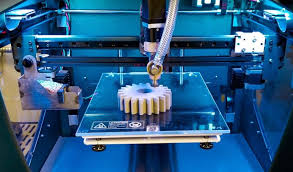

(3d printer)

Microparticles generated by 3D printing innovation are widely made use of in areas such as medication and vaccination distribution, microelectronics, microfluidics, and complicated manufacturing. However, mass customization of such bits is incredibly challenging.

r2rCLIP is based upon the continuous liquid user interface manufacturing (CLIP) printing technology created by Stanford University’s DiSimone Lab in 2015. CLIP utilizes ultraviolet light to strengthen the material swiftly into the wanted form.

The leader of the most recent research study, Jason Kronenfeld of the Disimone Laboratory, described that they first fed a piece of film right into a CLIP printer. At the printer, hundreds of shapes are at the same time published onto the film; the system then continues to clean, remedy, and get rid of the shapes, all of which can be personalized to the preferred form and material; lastly, the film is rolled up. The whole procedure, thus the name roll-to-roll CLIP, makes it possible for mass production of uniquely shaped fragments smaller sized than the size of a human hair.

(metal powder 3d printing)

Researchers claimed that before the development of r2rCLIP, if you wished to publish a batch of big bits, you needed to refine it by hand, and the process proceeded gradually. Now, r2rCLIP can create up to 1 million particles per day at extraordinary speeds. With new modern technologies, they can now quickly create microparticles with more intricate shapes using a range of products, such as porcelains and hydrogels, to create difficult and soft fragments. The difficult particles can be used in microelectronics making, while the soft particles can be used in medication delivery within the body.

The research group pointed out that existing 3D printing technology requires to find an equilibrium in between resolution and rate. Some 3D printing innovations can create smaller sized nanoscale bits yet at a slower speed; some 3D printing modern technologies can manufacture huge products such as shoes, family products, machine parts, football helmets, dentures, and listening device, yet they can not publish Great microparticles. The brand-new approach finds a balance in between manufacturing rate and fine range.

About Kmpass

Kmpass is committed to technology development, applications of nanotechnology and new material industries, with professional experiencein the nano-technology research and development and the application of materials.especially for 3d printing powder, 3d printing metal powder, 3d printing powder supplier, 3d printing for titanium powder. As a leading nano-technology development and product applications additive manufacturer, Kmpass dominates the markets. If you need high quality titanium metal alloy, please feel free to contact us.

Inquiry us